ETS-08005

Palletizing station with cobot and conveyor belt

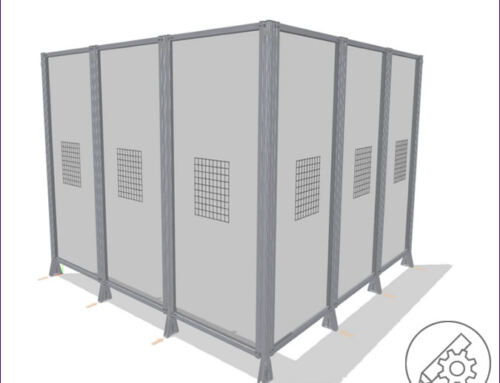

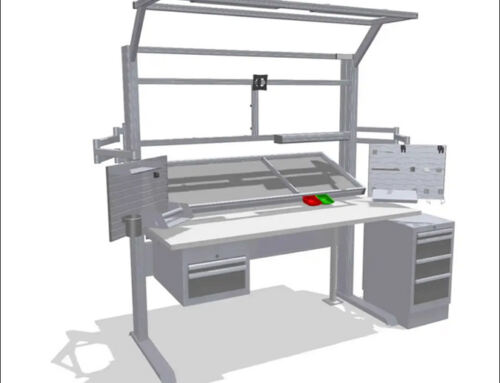

The scalable basis design combines a collaborative robot and a conveyor belt to create a variable palletizer. Packages are transported to the transfer point via the item conveyor belt. The Cobot automatically collates the packages onto load carriers.

The Cobot application offers two storage locations for pallets, which can be filled simultaneously or alternately. To ensure process accuracy, the height-adjustable feet can be fixed to the floor.

– The cobot is connected via the Robot Mounting Plate 8

– High rigidity thanks to frame made of Profiles 8 80×80

– Fixed to the floor using the Foot Clamp D80

– Free space in the robot column supports safe cable management

– Lateral brackets for sensors to secure the action area at the end connector

– Easily adaptable to different cobot models

– Type and dimensions of the conveyor belt freely adjustable

Note: Depending on the scaling of the solution, operating mode and robot model, the stability and design must be checked.

The price for this solution will be published soon.

Please note:

The “Starting at” pricing is an estimate based on the size and scale of the example shown.

Please contact your local sales representative to arrange a consultation to determine exact pricing for your project.