ETS-08004

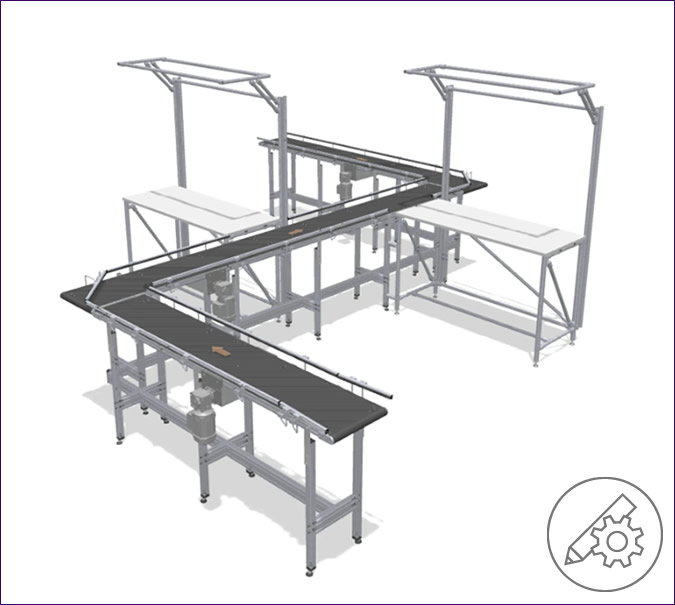

Workstation interlinking with conveyor belts in a Z-configuration

This application enables workstations to be interlinked even in difficult room layouts. If straight-line transfer is not possible, goods are gently guided from one conveyor belt to the next at a 90° angle. Thanks to the item center drive, the conveyor lines can be placed directly next to each other – without any obstructive contours at the transfer points. This allows the entire conveyor line, including infeed and outfeed, to be routed around pillars, walls or other structures.

For optimized linking of work processes, work benches can be placed on both sides of the conveyor belts in the required quantity. The drives can be positioned along the conveying route as required. A railing with slide strips and a horizontal roller in the corner area ensure a smooth transition between the conveyors.

You can easily adapt all details such as the height, width and length of the transport route, the type of conveyor belts and the equipment to suit the application using the item Engineeringtool. The workstations can be planned in detail in the item Work Bench Configurator.

The price for this solution will be published soon.

Please note:

The “Starting at” pricing is an estimate based on the size and scale of the example shown.

Please contact your local sales representative to arrange a consultation to determine exact pricing for your project.